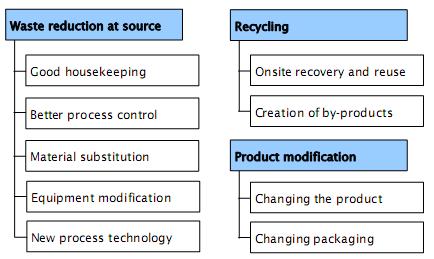

Cleaner Production Options relates not only to changing equipment, but also to the operation and management of the company. Cleaner Production Options can be grouped into:

Cleaner Production Options relates not only to changing equipment, but also to the operation and management of the company. Cleaner Production Options can be grouped into:- Waste reduction at source;

- Recycling; and

- Product modifications.

Waste reduction at source

Going to the source of pollution is the fundamental idea of cleaner production.

Good housekeeping is the simplest type of the cleaner production options. Good housekeeping requires no investments and can be implemented as soon as the options are identified. Good housekeeping is e.g. to repair all leaks and avoid losses by closing water taps and turning off equipment when not needed. Even though good housekeeping is simple, it requires focus from the management and training of staff.

Better process control is to ensure that the process conditions are optimal with respect to resource consumption, production and waste generation. Process parameters such as temperature, time, pressure, pH, processing speed, etc. have to be monitored and maintained as close to the optimum as possible. As with good house keeping, better process control requires improved monitoring and management focus.

Material substitution is to purchase higher quality materials that give a higher efficiency. Often there is a direct relation between the quality of the raw materials and the amount and quality of the products. Material substitution is furthermore to replace existing materials with some that are environmentally better.

Equipment modification is to improve the existing equipment so less material is wasted. Equipment modification can be to adjust the speed of an engine, to optimise the size of a storage tank, to insulate hot and cold surfaces, or to improve the design of a crucial part of the equipment. One example from electroplating is to construct drip hangers to recover drag out from the plated parts.

New process technology is to install modern and more efficient equipment, e.g. a highly efficient boiler or a jet-dyeing machine with a low liquor ratio. New process technology requires higher investments than the other cleaner production options and should therefore be considered carefully. However, the potential savings and quality improvements often pays back the investment in a very short time.

Recycling

Waste streams that are unavoidable might be recycled within the company or might be sold as by-products.

On-site recovery and reuse is to collect "waste" and reuse it in the same or a different part of the production. One simple example is to reuse rinse water from one process to another cleaning process.

Creation of by-products is to collect (and treat) "waste-streams" so they can be sold to consumers or to other companies. Excess yeast from a brewery can for instance be used for pig fodder, fish farming or as a food additive.

Product modification

Improving the products so they pollute less is also a fundamental idea of cleaner production.

Changing the product is to re-think the product and the requirements to the product. For instance, if it is possible to replace a painted metal shield with a plastic shield for a certain product, then the environmental problems and costs related to paint finishing could be avoided. Improved product design can result in large savings on material consumption and use of hazardous chemicals.

Changing packaging can be just as important. The key word is to minimise the packaging and maintaining the protection of the product. One example is to use recycled cardboard instead of plastic foam for protection of fragile items.